- Pumps

Self priming

Prime assisted

Standard Centrifugal

Gear pumps

- Applications

Construction and Mining

Industry

Government

OEM

- About us

- Support

- GR-Academy

- Contact

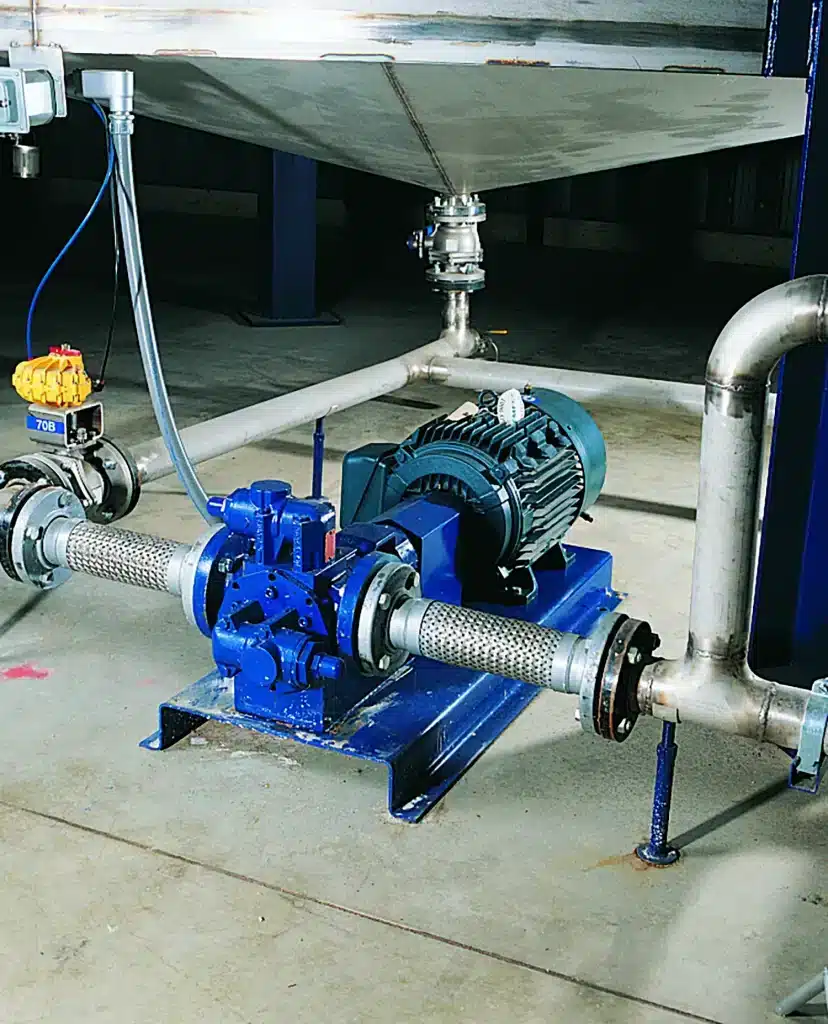

Gorman-Rupp gear pumps are built for precise fluid transfer, long-lasting reliability, and exceptional versatility. Whether handling light fuels, viscous chemicals, or abrasive liquids, these positive displacement pumps provide smooth, consistent flow for industrial, chemical, fuel transfer, and high-viscosity applications.

With patented features that extend service life and reduce maintenance costs, Gorman-Rupp gear pumps are a trusted choice for demanding environments.

Gorman-Rupp gear pumps are available in three duty levels to match your operational needs:

Material options ensure compatibility with different environments:

Gorman-Rupp rotary gear pumps handle a wide range of fluids, making them essential in industries such as energy, chemical processing, and food production:

Diesel, gasoline, kerosene, aviation fuels.

Motor oils, hydraulic fluids, industrial lubricants.

Acids, alcohols, ketones, and caustic solutions.

Asphalt, adhesives, resins, wax.

Chocolate, glucose, syrups, vegetable oils.

High-temperature fluids like MobilTherm and DowTherm.

Designed for smooth, controlled flow and minimal pulsation, these pumps are ideal for precise metering and bulk fluid transfer.

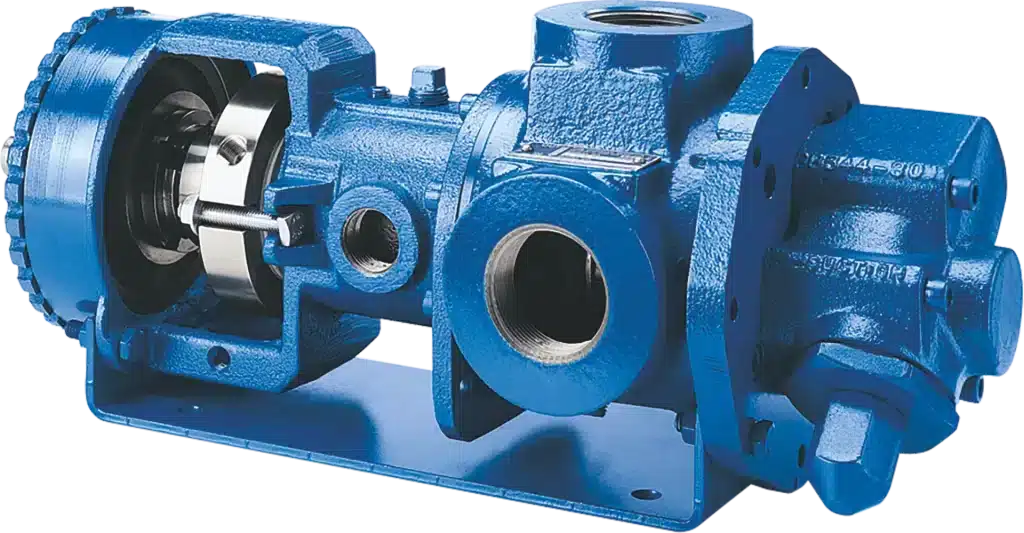

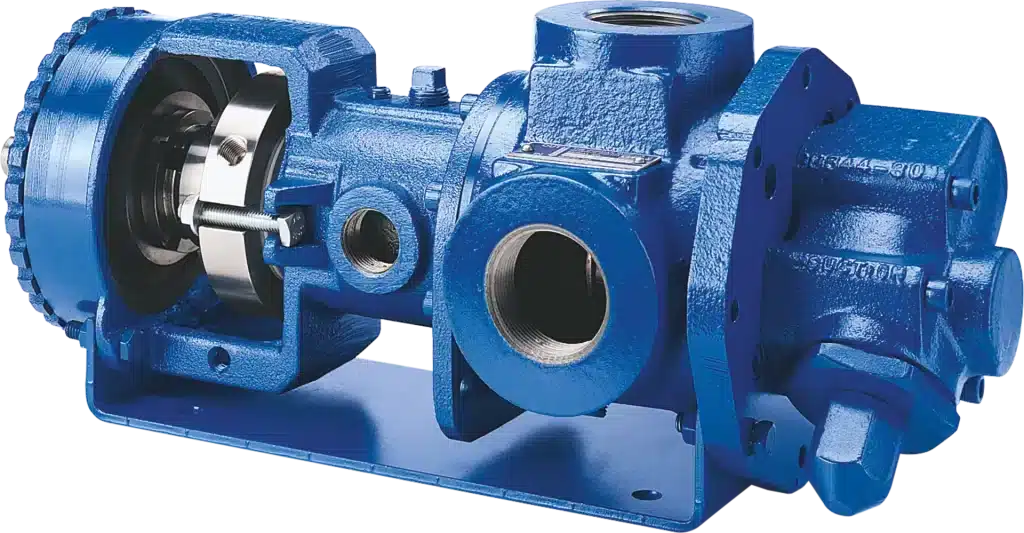

Gorman-Rupp’s G Series rotary gear pumps are engineered with exclusive technologies to ensure durability and efficiency:

These design enhancements ensure superior efficiency, minimal maintenance, and long service life, even in the toughest conditions.

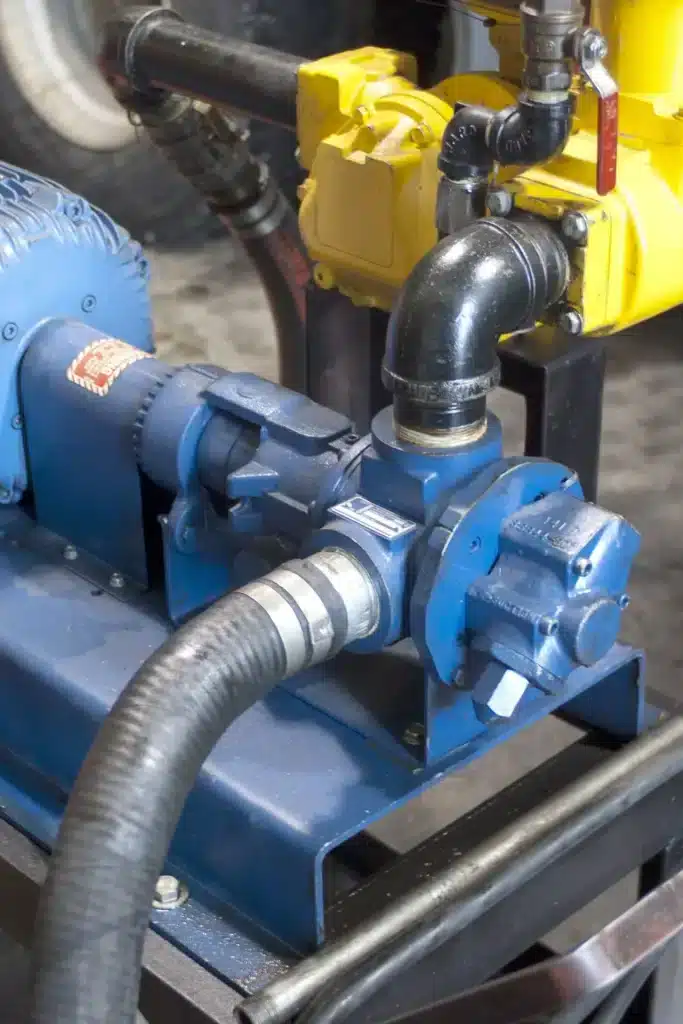

Gorman-Rupp gear pumps are designed for quick installation and hassle-free servicing, minimizing downtime and keeping operations running smoothly.

The result? Reduced downtime, lower maintenance costs, and improved operational efficiency.

With a strong reputation for innovation and quality, Gorman-Rupp continues to lead the industry in rotary gear pump technology.

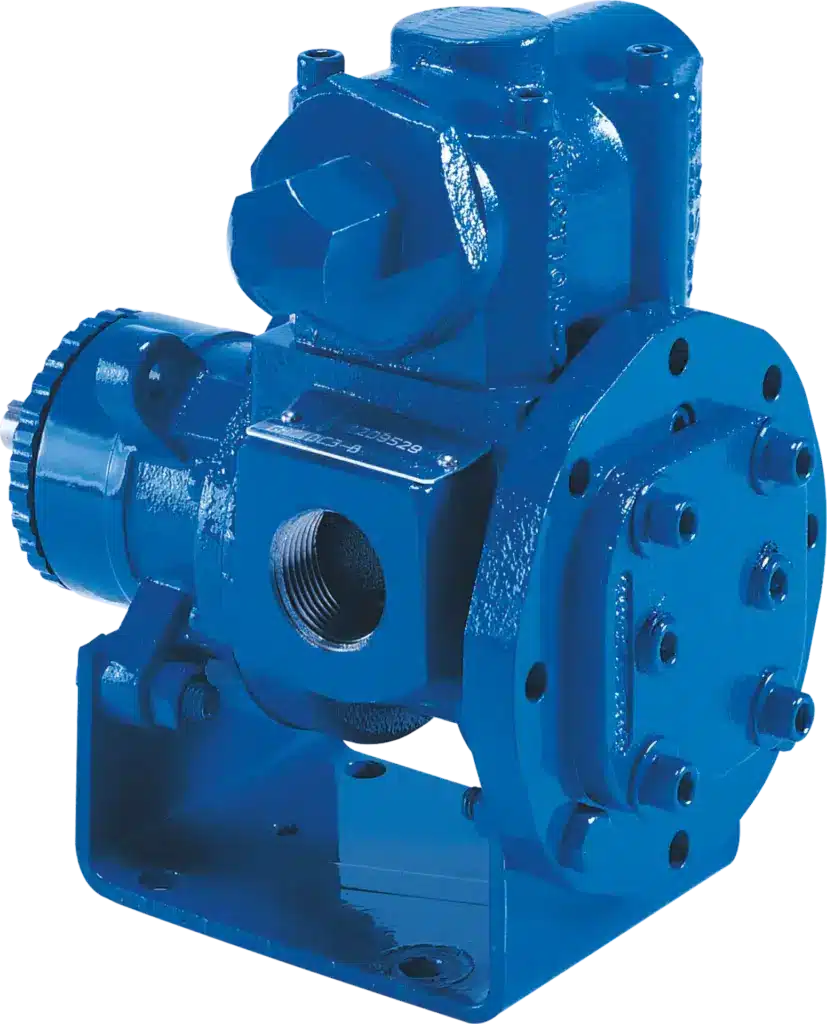

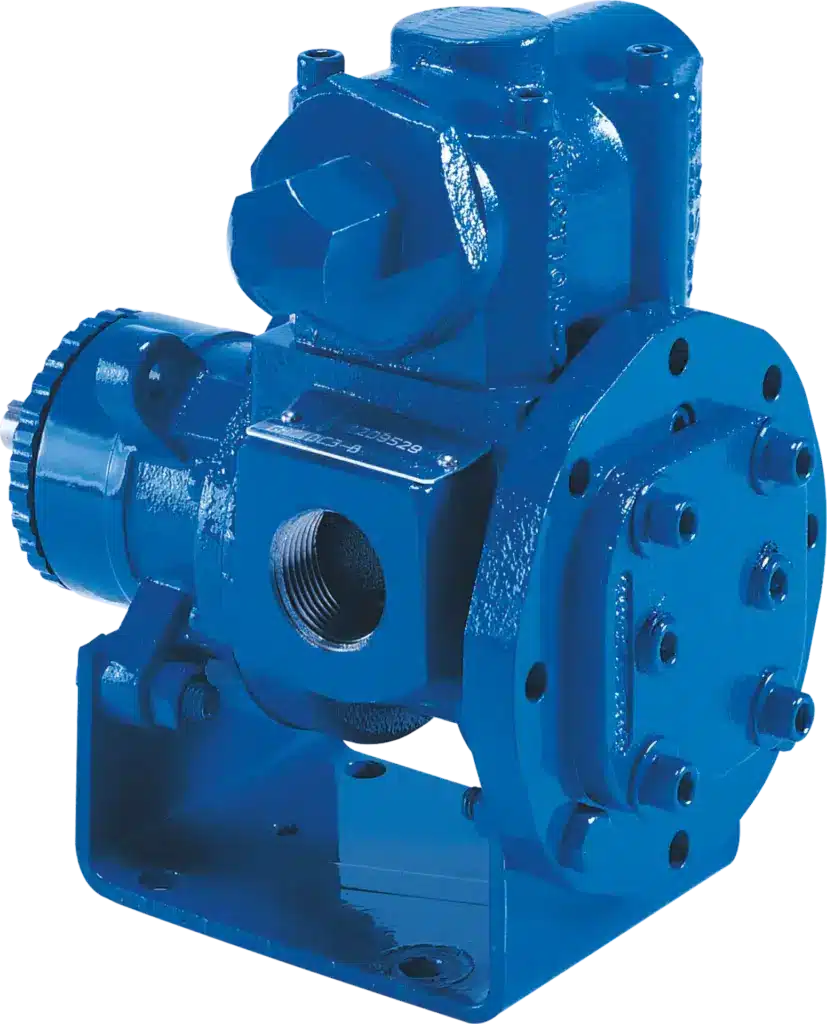

The Gorman-Rupp GMC Series® rotary gear pumps are compact, close-coupled pumps designed for light to medium-duty applications. With a space-saving design, they connect directly to other equipment, eliminating the need for additional drive components.

The Gorman-Rupp GMS Series® gear pumps are designed for intermittent or medium-duty applications, offering reliable fluid handling across a wide range of temperatures and viscosities. Available with head and backhead jackets, these pumps provide precise temperature control to maintain fluid consistency.

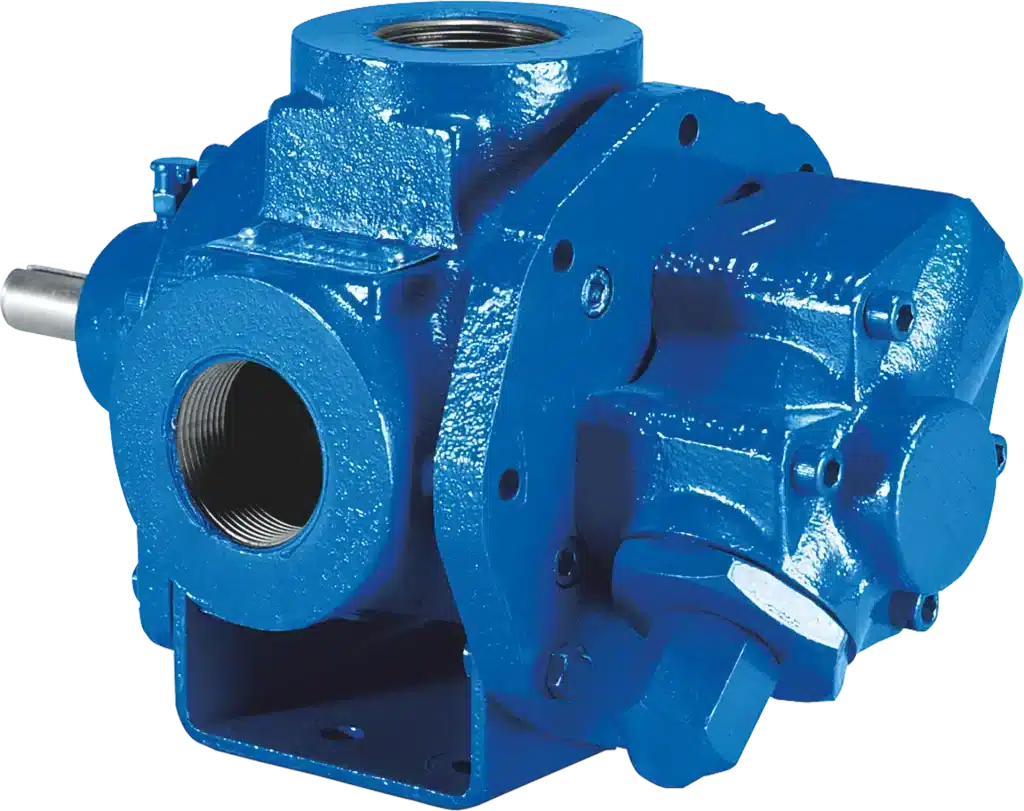

Gorman-Rupp’s GHC Series® rotary gear pumps are designed for continuous-duty applications, delivering durability, precise fluid handling, and long service life. Built from cast iron, cast steel, and stainless steel, they handle a wide range of viscosities, pressures, and temperatures, making them a reliable choice for demanding applications.

The Gorman-Rupp GHS Series® pumps are heavy-duty rotary gear pumps designed for continuous operation in demanding bulk liquid transfer applications. These pumps efficiently handle both thin and highly viscous fluids, making them ideal for industries requiring high flow rates and precise fluid control.

The Gorman-Rupp GHA Series® rotary gear pumps are built for one thing: getting the job done in the toughest conditions. Whether you’re dealing with slurries, abrasive chemicals or viscous fluids, these hard iron pumps are made to handle it- day in, day out.

A rotary gear pump is a positive displacement pump that moves liquid through the meshing of rotating gears. Each rotation traps a fixed volume of fluid and forces it through the discharge port at a constant rate.

G Series pumps are engineered for durability, serviceability, and adaptability. They feature rigid rotating elements, internal seal vents, and flexible sealing options that extend pump life and reduce maintenance costs.

These pumps can handle a wide range of thin and viscous liquids, including fuels, oils, asphalt, resins, adhesives, and even abrasive materials like titanium dioxide or printing inks.

The G Series includes GMC and GMS (medium-duty), GHC and GHS (heavy-duty), and GHA (extreme-duty) models, each designed for specific viscosity ranges and operating conditions.

Depending on the model, flow rates reach up to 600 GPM (2271 L/min) and pressures up to 300 PSI (21 bar).

Available materials include cast iron, ductile iron, cast steel, and stainless steel. Hardened and wear-resistant versions are also available for abrasive applications.

The deep end feed design and superior rotor support minimize deflection and ensure efficient pumping of liquids up to 2,000,000 SSU (440,000 cSt).

Yes. Depending on the model and material, operating temperatures range from -60 °F to 675 °F (-51 °C to 357 °C).

G Series pumps offer the industry’s widest selection: single, double, and tandem mechanical seals, cartridge styles, packing options, and quench or flush systems.

Thanks to the back pull-out design, maintenance can be done without disconnecting the piping. Adjustable no-leak valves and centralized supports simplify servicing.

Yes. G Series pumps can be supplied in various port styles, drive configurations (close-coupled, v-belt, engine-driven), and with optional jackets, relief valves, or wear-resistant housings.

They are used in petrochemical, chemical processing, paint, food, paper, and asphalt industries, where reliable handling of viscous or abrasive media is essential.

Features such as pressure-lubricated idler pins, hardened gears, and high-strength bushings reduce wear and extend operational life.

Yes. The design includes built-in adaptability, making them compatible with most existing gear pump installations.

All G Series pumps come with a one-year warranty and are backed by Gorman-Rupp’s worldwide network of factory-trained distributors and fast parts service.

Leave your name and email address below and receive the brochure directly in your inbox.

Laat uw naam en e-mailadres achter en u ontvangt de brochure direct in uw inbox.

Leave your name and email address below and receive the brochure directly in your inbox.