Cavitation is one of the most common and costly issues in pumping systems. It occurs when vapor bubbles form in a liquid and collapse with force, causing serious damage to pump components. For professionals working in industrial applications or dewatering, recognizing and preventing cavitation is crucial. This article explains what cavitation is, its consequences, and how the right pump choice – such as those from Gorman-Rupp – can help minimize its impact.

What is cavitation

Cavitation happens when the pressure in a liquid drops below its vapor pressure, forming vapor bubbles. As these bubbles move into higher-pressure areas, they collapse violently against metal surfaces, causing pitting, vibration, and noise.

How it develops

Cavitation is typically caused by:

- low suction pressure

- excessive suction lift

- inadequate fluid supply

- blockages or restrictions in the suction line

In dry self-priming pumps, cavitation can also occur when the pump runs dry too long or when air remains trapped in the system.

Recognizing symptoms

A cavitating pump often shows several clear warning signs.

Noise and vibration

A distinct “crackling” or “gravel” sound is a typical indicator. Increased vibration and fluctuating flow rates are also common.

Reduced efficiency

Cavitation lowers pump performance. The vapor bubbles disturb fluid flow, reducing discharge pressure and increasing energy use.

Visible wear

Prolonged cavitation causes pitting or surface erosion on the impeller and casing. This damage is often irreversible and significantly shortens pump life.

The effects of cavitation on pumps

The consequences of cavitation go beyond surface damage.

- structural erosion: bubble collapse causes microfractures that grow over time

- reduced capacity: flow and pressure decrease significantly

- increased maintenance costs: more frequent repairs and part replacements

- operational downtime: unexpected failures can halt production

A well-designed pumping system accounts for net positive suction head (NPSH). Gorman-Rupp pumps are engineered to perform efficiently within safe NPSH limits, effectively preventing cavitation.

How to prevent cavitation

1. verify the installation

Ensure proper pump placement. Keep suction lines short, straight, and airtight.

2. reduce suction lift

Position the pump as close to the fluid level as possible. The higher the suction lift, the higher the cavitation risk.

3. select the right pump for the job

Each fluid and application requires a specific solution. (link to pumps on Grpumpseurope.eu)

4. maintain your system regularly

Inspect filters, valves, and piping for blockages or air leaks.

5. use high-quality materials

Pumps with wear-resistant impellers and robust casings, such as Gorman-Rupp dry self-priming pumps last longer and better withstand cavitation.

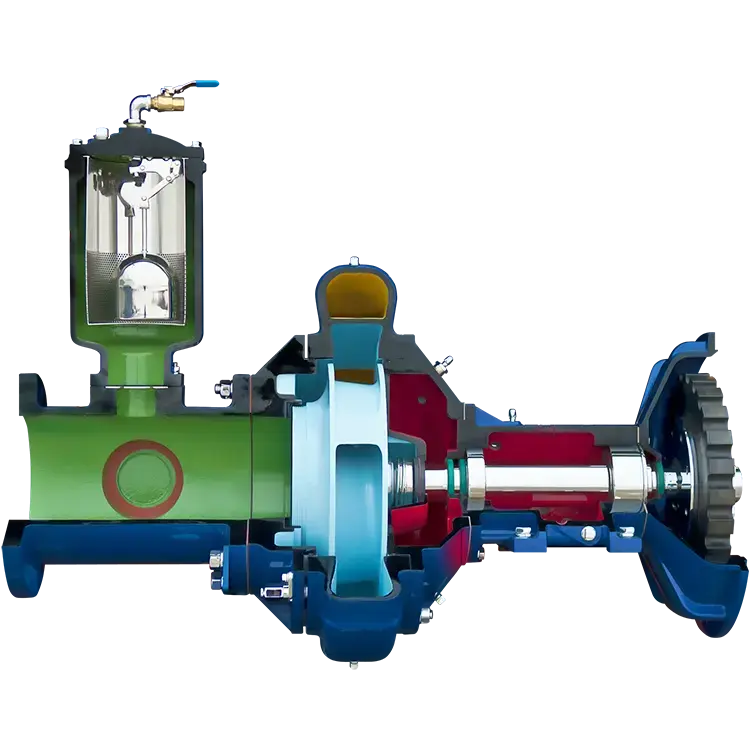

Cavitation in dry self-priming pumps

Dry self-priming pumps, commonly used in construction and dewatering, are less prone to cavitation thanks to their design. They can handle air without damage, as long as the fluid level remains within operating limits. Regular maintenance is still key to maintaining uptime and performance.

Summary and conclusion

Cavitation is a technical issue that can cause serious damage to pumps. It leads to erosion, efficiency loss, and unnecessary costs. With the right pump design, correct installation, and preventive maintenance, cavitation can largely be avoided. Gorman-Rupp pumps are known for their rugged construction, efficient design, and proven performance in demanding environments – ensuring your system remains reliable, efficient, and safe.